fresh news

Featured Story Welcome to Our New CEO, Patrick Criteser

We are thrilled to share that Patrick Criteser is joining our executive team…

Read More

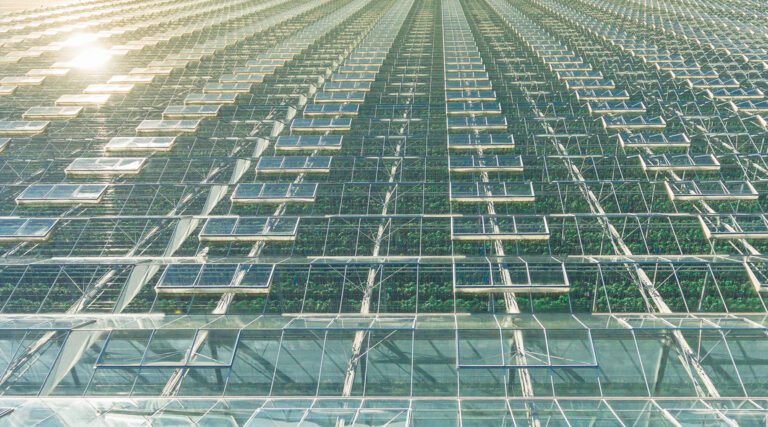

How We Grow

Building Momentum:

A New Partnership for Nature Fresh Farms

Nature Fresh Announces Minority Investment by Manulife Investment Management...

Read More

Healthy Lifestyles An Origin Story: Hiiros™ Tomatoes

When the Nature Fresh Farms team was first introduced to this new Tomato variety, we knew it was something special...

Read More

Healthy Lifestyles Protecting Heart Health

Support Your Heart with Fresh Nutritious Vegetables The food you eat can…

Read More

Healthy Lifestyles

Developing Healthy

Eating Habits

There’s no better time than now to think about adopting healthy eating…

Read More

How We Grow Welcome to Our New CEO, Patrick Criteser

We are thrilled to share that Patrick Criteser is joining our executive team

Read More

How We Grow Water Efficiency In Greenhouses

We believe in sustainable growing practices and are committed to reducing, reusing,…

Read More

Upcoming Event

![]()

Don't Miss

New Look.

Don't Miss

New Look.

New Momentum.

Come see us in Monterey, CA

at Organic Produce Summit,

July 9-10, 2025